Traffic Signs

Roads and highways are usually the best way to go from one place to another place that we all cross them every day. As we know, every year, many people around the world die in road accidents or suffer severe injuries, which will sometimes affect them for the rest of their lives.

Across this issue, many factors affecting in reducing these financial and human losses. The most important of them is standard guardrails which should be used correctly and principle and they are considered as an integral part of road safety.

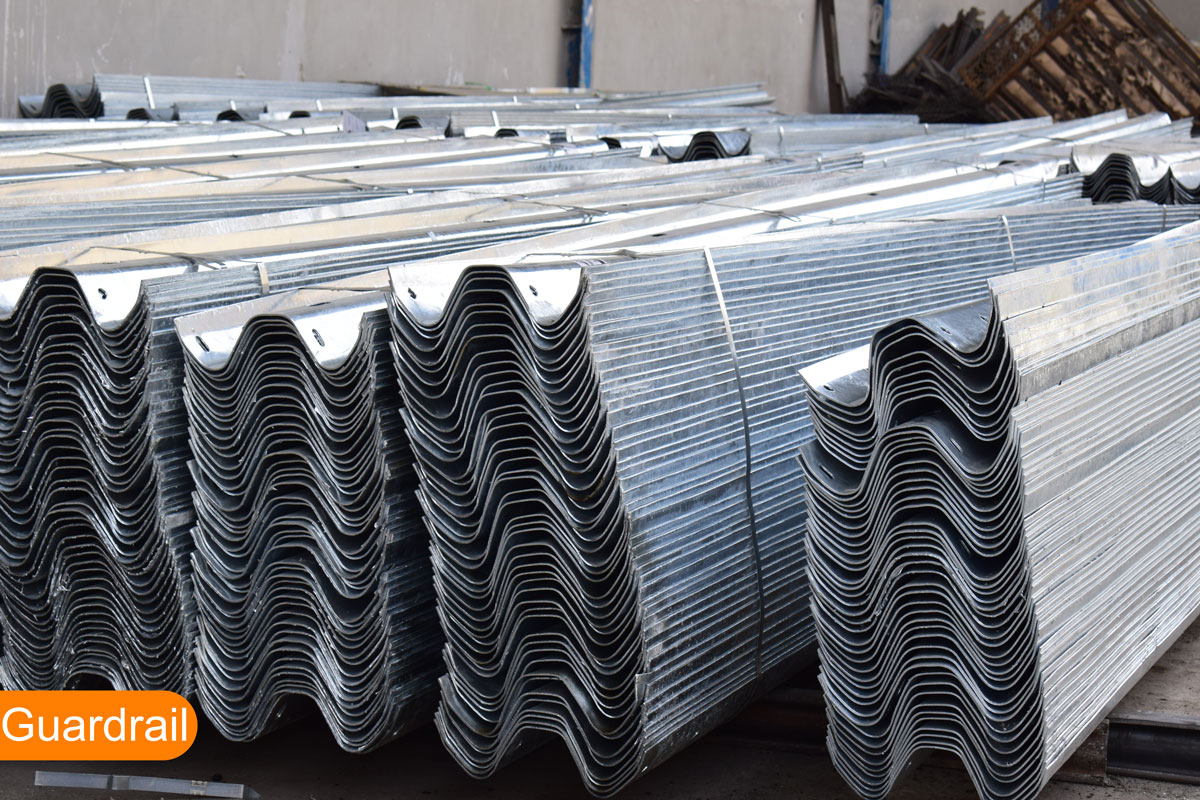

Guardrail

Road Safety

Road safety is one of the most important daily issue and is usually specified by the absence of accidents and casualties.

One of the main parameters of road safety is the guardrails installation which has a great impact on preventing accidents and accident resulting from it.

The main and important task of guardrails on roads and highways is to prevent accidents and reduce their severity. Related systems have been continuously developed since 1950 decade. The use of guardrails in many cases, by specifying the road bend and revealing the path of road, not only prevent the accident and vehicles deviation from the road, but also reduce the pressure caused by the accident to the passengers.

We have seen guardrails in different parts of the city until now. As we know, guardrails are used as a barrier to prevent falling off and impacting, also they are very useful in road safety. The guardrails application is a very important and fundamental process in preventing, reducing injuries and risks caused by blows and accidents.

To protect the lives of drivers, passengers and vehicles on roads and highways, we must install the appropriate guardrails in that area and region. There are different types of guardrails and many parameters are influential in its selection.

What is Guardrail?

Guardrail definition in English: guardrails are roadside and middle road guards that prevent vehicles and automobile from falling off, falling into the abyss, causing road accidents and damage. Another use of guardrails is to separate traffic from different directions on a highway.

Generally, guardrail is a type of longitudinal barrier used to protect drivers, passengers and motorcyclists from road hazards. The purpose of using guardrail is to reduce the severity of the collision by preventing vehicles from deviating from the road to the embankment or colliding with fixed objects, and also by showing the mazes of the road to be the best guide to show the route to drivers.

Sepehr Sanat Steela Factory is a manufacturer of various types of guardrails such: two-wave guardrails, three-wave guardrails, roadside guardrails, mid-road guardrails, as well as custom guardrails in accordance with the latest standards of CIS countries, Persian Gulf countries, neighbors of Iran such as Iraq, Afghanistan, Turkmenistan, Azerbaijan and Turkey, which by using world technical knowledge, also produces the hot-dip galvanized coating.

How to choose an appropriate guardrail?

Although the safety of vehicles is improving daily and modern vehicles and equipment are produced with high standards and safety, and there is also extensive training for drivers in this field, however there are always dangers that threats the lives of drivers. Wherever dangerous may occur on our roads, the use of protective equipment is an action that can save human lives.

As guardrails take care of people’s lives in the event of an accident, if the same guardrails are not selected, manufactured, assembled and installed properly and in accordance with the technical specifications of the road, they can cause irreparable damage.

Selecting the appropriate guardrail depends on some factors such as: road slope, road turns and curves, road width, road dirt, traffic volume, type of vehicles crossing through it (light and heavy vehicles) and maximum speed allowed.

We at Sepehr Sanat Steela Factory, having the most update equipment in the field of guardrail manufacturing, produce your custom guardrails. For more information and advice in the field of guardrail design and production, be in contact with our experts.

Necessity of Guardrail Installation

The most important asset of any country is human capital, which you must work hard to maintain their health and safety. According to increasing trend of using vehicles, attention to road safety is also increasing. From long ago until now, guards have been used along and in the middle of the road with the aim of increasing safety, reducing casualties and damages caused by accidents and traffic control. Therefore, equipping roads with safety equipment and standardizing it can have a significant impact on reducing accidents.

It is especially important to pay attention to the quality of guardrail and choose the best protector, since guardrails are installed with the aim of improving road safety. The properties and standard used for the guardrail, it must be such that it has the necessary resistance to the impact. Wrong choice can cause irreparable damage.

Guardrail Application Advantages

Guardrails are an integral part of every road and highway that must be properly manufactured, installed, assembled and repaired. Guardrails have numerous advantages that can be generally mentioned as follows:

- Increase the road safety

- Prevent the vehicle and automobile from falling

- Traffic control by separating round-trip lanes

- Reduce accidents and prevent the vehicle from deviating from the road

- Identify the road mazes

- Guide drivers at night

- Prevent animals from entering the road

- Specify the road area

- Environmental beautification

Types of Guardrails

There are different types of guardrails, each of which is appropriate for a specific location. Based on the elements mentioned above, guardrails are produced and supplied in different types. In this section, we will fully explain the types of guardrails for you.

Some of the influential parameters in selecting the guardrail proportionate to the environment are:

Material, hardness and flexibility, installation position, performance and degree of permeability

We can divide guardrails into two groups according to the type of materials used in them:

Metal

Concrete

New Jersey Barrier or New Jersey Wall which due to having the same color and material as the cement block, is commonly called “New Jersey block” in Iran and it made parts of concrete or plastic which main usage is to separate road traffic routes from each other, however, they are also used to block passages or roads. These parts are designed to cause less damage in the event of a collision and impact with the vehicle and automobile, while preventing the vehicle from crossing in the opposite direction and accident (so-called crash head-on accident).

New Jersey separator is one of the standard and famous models that can support up to 18 tons if installed correctly according to the standards.

Guardrails are divided into three main groups in terms of hardness and flexibility:

Flexibility

These fences are resilient and show flexibility when the vehicle collides with a side guardrail and are divided into three categories: three-cable, two-wave beam and three-wave beam.

Three-cable Fence: As the name implies, they consist of three steel cables and a post. These cables are installed on the post. The initial cost of setting up a three-cable fence is lower than the rest. Other features of this model include good performance in sandy and snowy areas, support for a wide range of vehicles, open design and etc., but the need for large space behind the fence due to its resilient feature, replaces a large part of fence after the accident, inefficiency in arched places and etc. are the disadvantages of this model.

Two-wave Beam System: The two-wave guardrail has performance quite similar to the cable system, but the important difference is that it has much less lateral deformation than the cable type. Therefore, the back of the guard requires the least empty space. This type of guardrail is also capable of covering vehicles weighing 8.0 to 8.1 tons and in the event of a collision of 1800 kg-vehicle with an angle of 28 ° and a speed of 95 km/h, will have the amount of lateral deformation equal to 2.2 meters. The upper limit of this guardrail servicing is 2100 kg-vehicle with a collision angle of 24 ° and a speed of 95 km /h. This system is sensitive to the installation height as well as the elevation of the ground, so the installation height must be carefully observed in the implementation.

Three-wave Beam System: It is quite similar to two-wave W-shaped guard and differs from the two-wave guard in its beam, which can cover a wider range of vehicles with different heights. In addition, it is less sensitive to the ups and downs of ground. To prevent the beam from twisting, the system must be hooked alternately from top to bottom.

Semi-rigid

The flexibility of these guards is less than previous cases, so they show little flexibility when the vehicle collides and are available in three models:

Box-shaped Beam: This guard is in the form of a box with weak posts and it is designed in such a way that can transfer the applied force when the vehicle collides with the adjacent post. Its strength is obtained from the amount of strength, bending resistance and tensile strength of the beam.

Two-wave Beam with Strong Post: The design of this guardrail is such that a piece is placed between the post and the beam, which reduces the possibility of vehicles falling. Its strength depends on the tensile strength of the beam and post.

Modified Three-wave Beam: This model is similar to a three-wave beam, except that when the vehicle collides with it, the edge of the piece and the beam will be bend, resulting in increased resistance and the possibility of supporting large vehicles such as bus. The cost of repairs is less than the previous models, so regardless of its cost, it is the best model of guardrail.

Rigid

These models of fences have less flexibility and remain fixed when the device collides with them. They are designed and installed in different types such as:

Concrete guard with variable cross section: These types of guards are fragile and sensitive in severe accidents, so when producing and installing them, all aspects must be carefully examined to be accurately and attractively connected to the ground.

Type of Guardrail in Term of Installation Position: Guardrails are divided into two groups in terms of installation position:

Side Guardrail: It is a longitudinal guard that is used to protect drivers against natural and artificial obstacles located next to the roadway. This guard can also be used to protect pedestrians and cyclists against motor vehicles.

Middle Guardrail: It is a two-way longitudinal guard that is installed in the middle of the passage.

Type of Guardrail in Term of Performance: The bumpers are classified as follows:

Redirective Crash Cushion: These bumpers steer the off-road vehicle from the road into the mainstream traffic. In places where there is a possibility of collision of the vehicle from the side, use the Gating Crash Cushion.

Accelerator Guardrail: These bumpers gradually reduce the acceleration of the off-road vehicle until the automobile is completely stopped. Where the vehicle is likely to collide head-on, accelerator bumpers should be used.

Type of Guardrail in Term of Permeability: The bumpers are classified as permeable as follows:

Penetrable (Gating Crash Cushion)guardrail: Due to the collision, there is possibility of vehicle penetration in this type of bumper and its entire length can lead the diverted vehicle to the main flow of traffic.

Impenetrable (Non-Gating Crash Cushion) guardrail: Due to the collision, there is no possibility of vehicle penetration in this type of bumper and its entire length can lead the diverted vehicle to the main flow of traffic.

Advantages of Manufacturing Steel Highway Guardrail

System

There are many types of guardrail system production in the market today. However, only systems that made of steel can make the safest guardrail with minimal impact.

- Complete protection of the vehicle and automobile

- Minimize injuries to the passengers

- Easy installation

- High resistance and strength

- Easy maintenance and repair

Zinc metal coating has been used on these galvanized structures to be resistant to environmental damage and also coating existence can prevent the corrosion of the impacts caused by the collision of vehicles to some extent.

Designing and engineering these guardrails are in such a way that they do not be required maintenance or painting. Of course, in case of heavy impacts, they would undergo changes, according to its modular design, can be compensated by replacing one or more small parts or quick and inexpensive repairs.

Modular design means the structure construction is from smaller parts and components, which allows that if part of it is destroyed, there is no need to move and repair the entire structure.

Components of Various Types of Guardrails

Guardrails have different parts such as beam, post, spacer, specific bolts and nuts, reflectors and steel sub-connections, each of which has unique specifications according to the purpose of their fabrication.

Finally, these beams are connected using bolts and nuts. Follow us to get acquainted with the complete specifications of all these pieces.

Beam

In Sepehr Sanat Steela factory, depending on the standard type, beams are produced in 2 lengths of 4300 mm. and 4170 mm with a thickness of 205 to 3.5, the useful length of each of which respectively is 4000 mm. and 3180 mm.

There are two types of coating for sheet: hot dip galvanizing and electrostatic painting.

Post

The guardrail post, as a very important part of the guardrail, is supposed to support other guardrail components such as beams, spacers, etc. The posts generally determine the guardrail function and they can be divided into ordinary steel posts and flange posts. In general, steel posts are mainly fixed by the post machine in the ground, while the edged-posts or so-called baseplate are fixed with bolt and nut on concrete ground. We offer and supply different types of posts to the customers as a prominent manufacturer of guardrails in Iran: Zigma post, C post, U post, girder, gutter and square shape post (box shape) and can also produce the different posts according to the customer’s needs which are based on the standard.

Spacer

This piece is installed between the post and the beam and absorbs the energy of the accident. It is produced in both one-side and two-side modes. There are different types of spacers and they are produced in different shapes and dimensions depending on the standard type of that system.

Bolt and Nut

One of the most important and necessary pieces of the guardrail are bolts and nuts. It may be interesting to know that these small pieces have a great impact on the guardrail resistance and strength. Bolts and nuts of guardrail that connect the beam to each other, can cause irreparable danger if they are not selected properly or if they are not of good quality and standard material. Another use of bolts and nuts is in baseplate guardrails. The coating of bolts and nuts is also hot galvanized.

What are the Essential Guardrail Accessories?

In addition to the main parts used in the guardrail, a number of accessories are also used in the guardrail which can be said to be one of the most necessary and important pieces of the guardrail accessories. As these accessories are the main part of the highway guardrail which can greatly affect the safety of the guardrail. Accessories can greatly increase the guardrail safety. Guardrail accessories include: connectors, posts, post covers, trapezoidal night colors and etc. each of which has its own unique feature.

3 Essential Guardrail Safety Tips

In addition to the material used in the guardrail construction, many factors affect the safety of guardrail that should be paid special attention to them:

- Assembling all guardrail pieces

Assembling all guardrail pieces is very important and essential and should be done professionally and specialized by an experienced person.

2.Installing guardrail

Experience has shown that if the guardrails are not installed by using the appropriate equipment with expert technicians, not only they do not have their useful performance, but also they cause irreparable damage.

- Ability to Supply Guardrail Accessories for 20 Years

One of the most important points when buying a guardrail that we should pay attention to it, is the ability to supply guardrail accessories for 20 years. Sepehr Sanat Steela meets this customers’ require.

Sepehr Sanat Steela Guardrails Features

In Sepehr Sanat Steela factory, with the aim of saving human lives and minimizing damage caused by accidents, lines of manufacturing, assembling and designing are working.

Produced guardrails in Sepehr Sanat Steela factory have the following characteristics:

- Resistant to corrosion and rust

- Durable and well made

- Designed for long-term use

- Easy installation and repair

- No maintenance required

- Absorb maximum energy of impact force

- Protect vehicles from slipping on roads, especially mountain roads

and bridges

- Affordable and has longevity

- Made of very high quality steel sheet

- Shockproof and has high safety

- Anti-corrosion, anti-erosion, quick and easy installation

- Can be used anywhere.

- Ability to design for any specific and unique standard

The Last Word

Sepehr Sanat Steela Factory with more than 20 years of experience, is a manufacturer of highway guardrail in accordance with the Iranian and European standards in Iran. We are proud that we have been able to produce the best type of Iranian and European road and highway guardrails in the field of guardrail production by using the most up-to-date equipment in the world and using standard materials. To get more information about the guardrail and its price, please be in contact with our experts.